Stainless Steel Sanitary Inline Shear Circulation Emulsifying Pump

Name: Sanitary in-Line High Shear emulsifying pump BRL3 Material: SS304, SS316 Operation Principle 1. High shear dispers

Basic Info

| Model NO. | BRL3 Series |

| After-sales Service | Online/Spare Parts/Life-Long Aftersale Service |

| Warranty | 1 Year |

| Mixer Type | Homogenizer |

| Working | High Speed Mixer |

| Stirring Type | Forced |

| Application | Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid |

| Certification | CE, ISO |

| Application Area | Food |

| Layout Type | Horizontal |

| Mixing Drum Shape | Conical |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Pump Power | 1.5-132kw |

| Pump Speed | 2800rpm |

| Pump Flow | 0-130t/H |

| Pump Material | Ss304 or Ss316L |

| Transport Package | Plywood Case |

| Specification | ISO, CE, UL |

| Trademark | L&B |

| Origin | Zhejiang |

| HS Code | 8479820090 |

| Production Capacity | 1000 Sets Per Month |

Product Description

Name: Sanitary in-Line High Shear emulsifying pump BRL3Material: SS304, SS316

Operation Principle

1. High shear dispersing emulsifier effectively, quickly and evenly disperse a phase or usually, there phases are dissolvable to each other.

2. The rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect ,therefore ,the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing ,centrifugal force, pressing ,liquid fraction, clashing ,tearing and rush water .

3. The dissolvable solid ,liquid and gas material is then instantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made.

We are specialized in producing different kinds of Colloid mill, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.

Please contact us if you have any needs.

| (kw) | (rpm) | m³/h | |

| Model | Power | Speed | Flow |

| BRL3-60 | 4 | 2800 | 0-4 |

| BRL3-100 | 7.5 | 2800 | 0-8 |

| BRL3-120 | 11 | 2800 | 0-12 |

| BRL3-140 | 15 | 2800 | 0-18 |

| BRL3-165 | 22 | 2800 | 0-22 |

| BRL3-200 | 37 | 2800 | 0-30 |

| BRL3-220 | 55 | 2800 | 0-40 |

| BRL3-240 | 75 | 2800 | 0-55 |

| BRL3-260 | 90 | 1480 | 0-65 |

| BRL3-300 | 110 | 1480 | 0-80 |

| BRL3-360 | 132 | 1480 | 0-100 |

| BRL3-380 | 160 | 1480 | 0-120 |

| BRL3-400 | 185 | 1480 | 0-140 |

| Product Name: | 3 stages high-speed shear mixer pump for palm oil |

| Description: | Designed according to GMP standard, widely used for transfer viscous media in the food-processing, cosmetics and pharmaceuticalindustries |

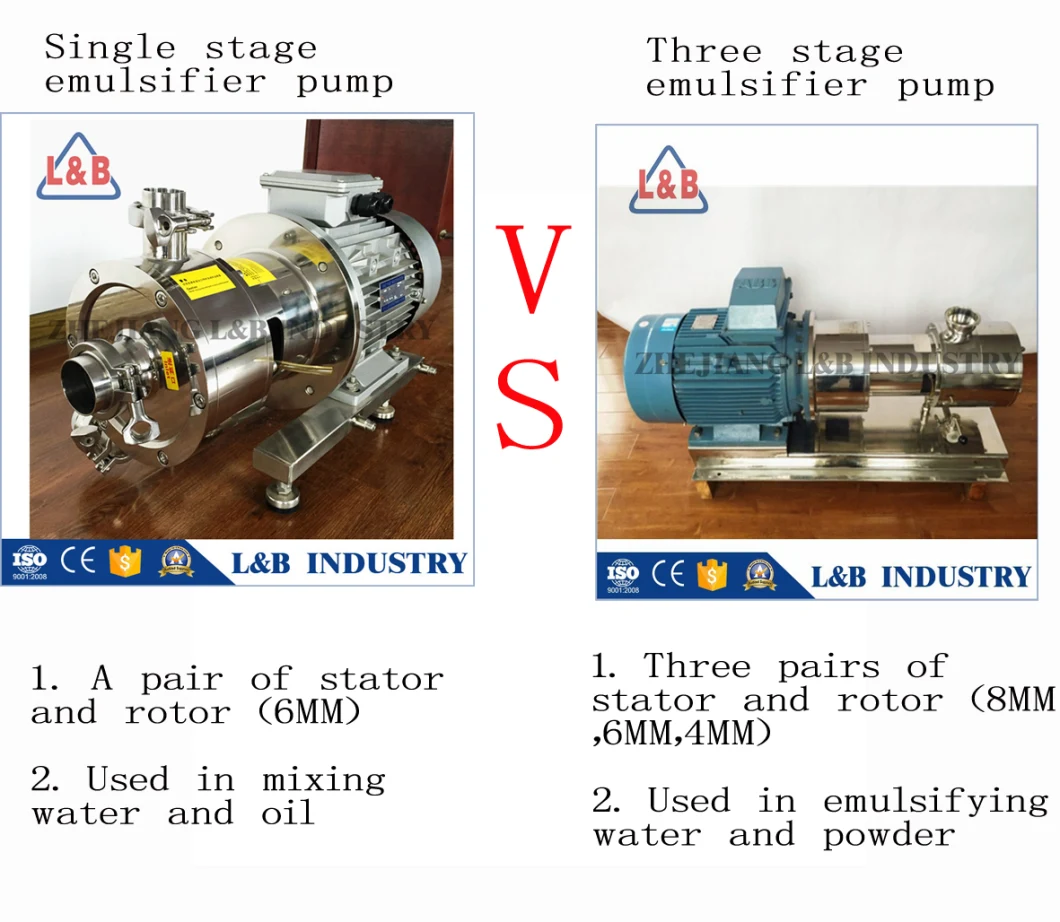

| Construction: | 3 stage rotor and Stator series(CNC treatment) |

| Material: | SS304/SS316L |

| Flow range: | 0-130T/H |

| Outlet Pressure: | ≤0.2 MPa. |

| Speed: | 2800-2900 rpm (Frequency Converter Control can be choose) |

| Rotor Type: | teeth |

| Teeth space: | 2.2kw 4mm; > 2.2kw 6mm |

| Rotor and stator space: | Standard 0.5mm(optional 0.25mm-0.5mm) |

| Motor power: | 1.5kw, 2.2kw, 4kw, ...75KW |

| Sealing option: | Sanitary single mechanical seal/Dual End Mechanical Seal |

| Seal material: | FKM |

| Max feeding medium viscosity: | < 3000CPs |

| Voltage: | 110-480V, 50hz/ 60hz |

| Bearing: | Japanese NSK |

| Motor: | Siemens, ABB, LOCAL etc. |

| Surface treatment: | Inner polished and Sandblast outside |

| Available connection: | Clamp, Union, Flange etc. |

| Available standard: | DIN, SMS, 3A, RJT, ISO/IDF |

| Operated: | Electric |

| Application scope: | Dairy, food, beverage, pharmacy, cosmetic, etc |

| Packaging Details: | Plywood case Or as per the request of customers |

Send to us